We build robust and cost-effective Stenter

As a leading manufacturer of hot air stretching stenter in China, Yonliton has been focused on hot air stretching and finishing process of varies types of textile fabrics, suitable for heat setting of knitted, woven warp knitted and plush fabrics, thus giving the end product perfect hand feeling, lustrous appearance and predetermined width.

What You Need To Know About Yonliton Stentering

Yonliton Printing & Dyeing Machinery Co,. Ltd(永利通印染机械有限公司) was founded in 2008 in Xinchang County Zhejiang province in China . Since then, we have established modern factories and advanced processing equipment. We have always been dedicated to innovation of high productivity and low energy dissipation finishing machine for various types of high-end fabrics.

In 2023, Yonliton established the Shaoxing Doctor Innovation Station, which has been successively awarded the National High tech Enterprise, Zhejiang Science and Technology Enterprise, Zhejiang High growth Science and Technology Enterprise, etc.

Our Products

State of art energy saving finishing machine

-1024x449.webp)

Energy-saving CNC hot-air stenter(high-end knitted fabric)

Stenter designed for high-end knitted fabrics, suitable for acrylic, nitrile, cotton, modal, rayon and other knitted fabrics, as well as high-end warp knitted fabrics (air layer, lace).

Energy-saving CNC hot-air stenter(plush fabric)

Stenter customized for plush fabric, applicable to stretching, setting and pad dyeing of weft knitted and warp knitted plush cloth, which is energy saving, safe and efficient.

Energy-saving CNC hot-air stenter(woven fabric)

Stenter designed for woven fabrics, suitable for woven cotton (denim, canvas, etc.), woven synthetic fiber cloth (chiffon, four-sided elastic, bag cloth, wall cloth, home textile cloth, curtain cloth, etc.)

What Services We Offer For You

Implementation

We will arrange our techinicians promptly to guide your staff through installation of all set of equipment from scratch,ensure that the machine is running in optimal condition.

Remote Diagnostics

Rapidly troubleshoot through online tutoriol and solve problems, reducing downtime to maximize your productivity.

Energy Consumption Analysis

Real-time information on both energy and electrical consumption is collected, and modifying the parameter enables huge increase in energy efficiency.

Latest News

Video of ITMA ASIA 2023 YONLITON

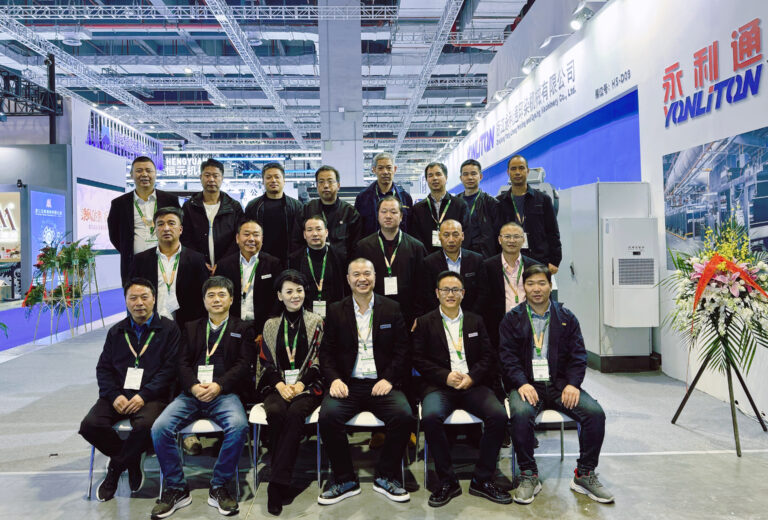

Interview from Master’Cai with GM Mr. Wang in Yonliton stand in ITMA ASIA + CITME 2023 in Shanghai

African printing and dyeing factories purchase stenters promptly, how Yonliton embarks on the fast lane?

Interview with Master Cai:” The current world’s economic situation is unclear, it is a…

Have A Blueprint of Upgrading Your Fabric Production Line?

Equip your textile factory with our brand new stenter, thus substantially lower the cost on electricity, natural gas and water .